产品详情

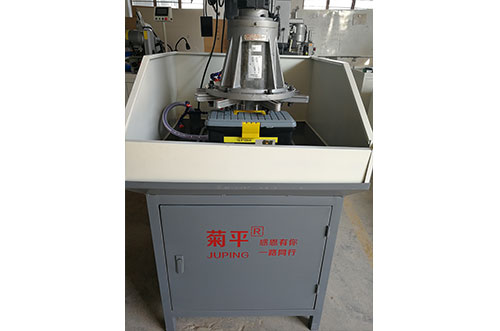

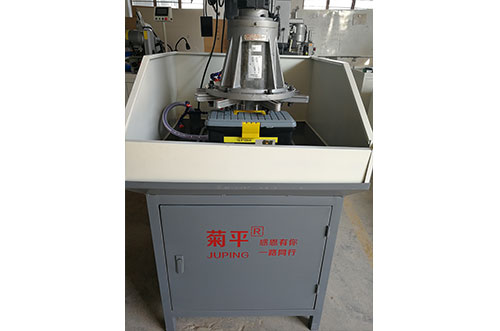

GT3-231

Precision automatic GT series (erect)

Model:GT3-231◆Easy operation (tread operation), no manual work is needed.

◆Automatic reversal device, free adjustment of high precision tapping stroke

◆Special double safety clutch to prevent the screw from breaking

◆High precision, vertical stability and easy operation, the perfect thread that can not be realized by a general tapping machine, such as tiny and superfine teeth, can be made.

◆The self-made key switch and the special motor are all closely tested, strong and durable

◆A timing function that can be used for a long and high speed continuous cycle and a one-way cycle.

◆Automation is the best choice for unmanned and beginner

◆Multi axis tapping device can be installed on demand to improve production efficiency

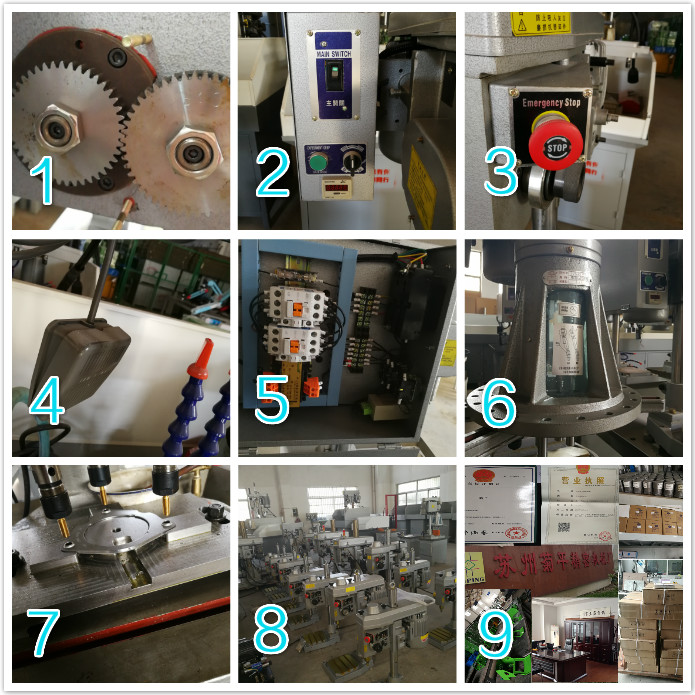

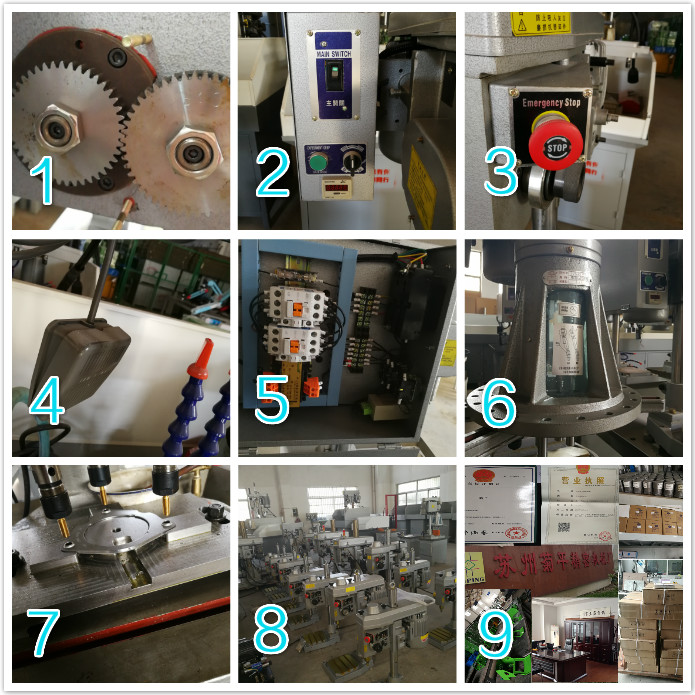

Product advantage

1. The machine adopts tooth distance gear drive, 0 error and high precision.

2. With the technical function, the point move to the knife.

3. Emergency stop button, safer.

4.Foot switch control, one time and back, more convenient.

5.Standard wiring mode, Schneider or LE and other well-known brand parts.

6.It can be equipped with a multi - axle device to make a hole position at one time.

7.Non - standard customization, more targeted.

8.There is plenty of stock and the delivery time is fast.

9.Regular manufacturers, registered trademarks, quality assurance.

Specification table |

Maximum spindle stroke mm | 65 |

Screw diameter mm | 460 |

Screw diameter mm | M10 ~ M32 (45#钢) |

Top and lower range of head mm | 450 |

The distance between the main shaft end and the platform mm | 600 |

Workbench size mm | 340 × 380 |

Base area mm | 600 × 480 |

Shape size (long * wide * high) mm | 600×480×1200 |

motor | 3mutually 6P 1.5KW (2HP) |

Spindle rotation number | 50HZ | 200, 100, 50 |

60HZ | 240, 120, 60 |

Conforming to the use of this machine

Automatic send pitch | The number of teeth per inch | 19, 16, 14, 12, 11, 10, 9, 8 |

mm | 1.5, 1.75, 2.0, 2.5, 3.0, 3.5 |

Multiaxial maximum capability (m/mStandard pitch) | M10×10axis M16×4axis M20×2axis |

weight | 约 250kg |

>>rotation--Precision automatic feeder combination of tooth distance:

The replaceable A, B gear and the A, B shaft and the main shaft are fully matched with the tooth pitch (without this device) this combination has the following advantages:

1、Vertical stability, precision and stability:

Precision is quite high. Screw attack does not need to work hard when moving forward or backward, while producing excellent processing articles will not cause different threads. The soft products such as the punching machine or the light metal, the synthetic resin and other soft products can also be made to perfect thread. There is no quality instability or bad phenomenon.

2、The processed items are not going up when the tapping machine is processed:

It is not necessary to press the processed objects with the hand, and the processed objects will not jump up.

3、Easy operation and promotion of work efficiency:

As the processed items are not jumping up, so long as they do not have to press the simple device of the processed objects, they can play the highest working efficiency.

>>The operator's hands are free to leave the machine:

Positive rotation, reversal, positive rotation and reversal... The single cycle of continuous cycle and forward turn to reverse and stop is operated by a specific key switch. In addition, a pedal switch can be installed for selective operation, and continuous cycle and one-way circulation can be automatically operated. The hands of the operator can safely leave the machine.

·For a long time, high speed and continuous circulation, strong and durable:

The GT1-203 type continuous cycle runs forty times per minute, which can be operated continuously and continuously at high speed, especially using our own electronic key switch and special motor, which can last ten million times.

>>The beginner can operate smoothly:

Single acting continuous are automatic cycle operation, operator's hands can completely leave the machine, as long as the supply of processed goods, beginners and skilled persons working efficiency of the same.

>>Simple adjustment of high precision tapping stroke:

Automatic reversing device can adjust the stroke of the attack freely, the shallow hole and the machined object with the bottom of the hole, and can also be easily adjusted.

>>Double safety device can prevent screw from breaking:

Spindle rotation and up and down, advance and retreat tools, special dual safety clutch, the spindle can automatically stop, reverse return does not wear cutting tools.

>>A multi axis tapping device can produce efficient operation:

It can be equipped with a multi - axis tapping device with high production efficiency. |

※Standard accessories: | a.1 Toolboxes b.1 groups of tooth pitch gear,Specifications are specified by the customer c.The chuck body and the CT-12 each 1, or 3/8 "drill 1 optional one.

Note: because of the continuous research and improvement of our products, the mechanical specifications of this website have the right to change, without notice.

|